http://mpora.com/videos/r6SP2DtVL If you’ve ever wondered what goes on inside your rear hub then check out this in depth feature…

The Freehub Body – how it works

Hopefully you should now be feeling a bit more confident to delve inside your hub and give it some love. It’s worth pointing out though that you should really take your cassette off first. Whilst you can reassemble some designs even with the cassette in place it just makes life easier if you take it off, and with other designs you have no choice so you might as well do it just to make sure. Shimano hubs and some cheaper cartridge bearing hubs have a sealed freehub body design so you can’t really service these, instead they’re a case of replace when knackered.

If you didn’t quite catch some of the detail in the video, or just want a closer look at the inner workings, then here are some close up shots and even more information on all things freehub…

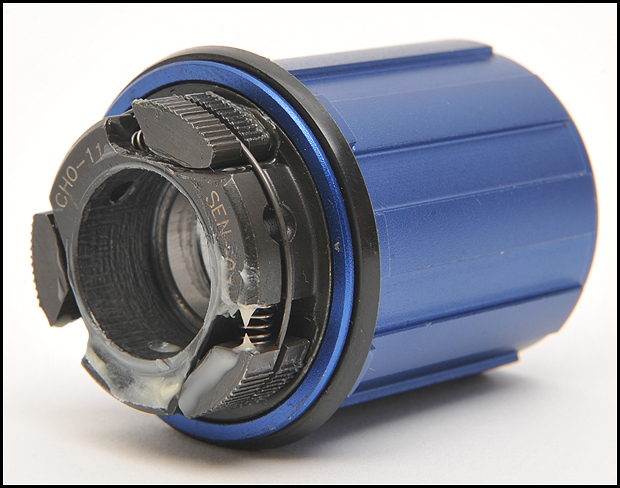

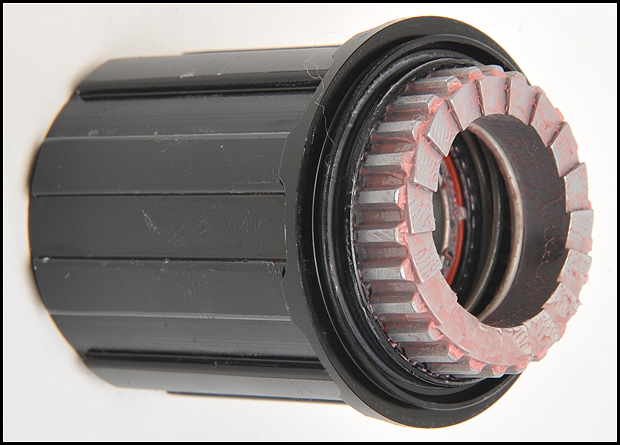

The ratchet and pawl system that you find inside a Hope hub is by far the most common design. The finer details may change a little between makes, but the overall principal is the same. Some use leaf springs like Hope whilst others use tiny coil springs, and some use a retaining ring to hold everything in place whilst others (annoyingly) don’t bother at all and those ones are a little more fiddly to put back together…but you can do it!

DIRT MOUNTAIN BIKE | BIKE REVIEWS

The number of pawls can also vary between designs, but in general the more the better. To produce a faster pick-up some companies also offset the pawls so as to double the number of engagements per revolution. So you might have six pawls but only three are actually engaged at any one time.

The ‘ratchet’ part of the ratchet and pawl system. Big teeth and pawls will deal better with larger amounts of torque, but on the other hand a finer set up will give you faster engagement. Like so many other parts of a bike it’s a balancing act, and that’s why as I said before several companies have chosen to go down the offset pawl route rather than making things finer.

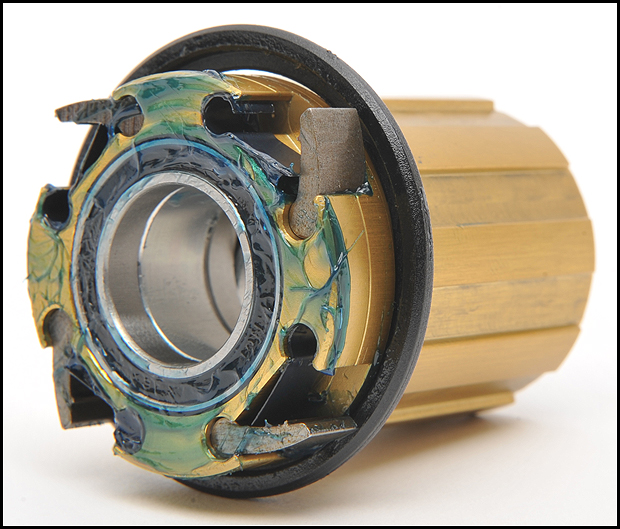

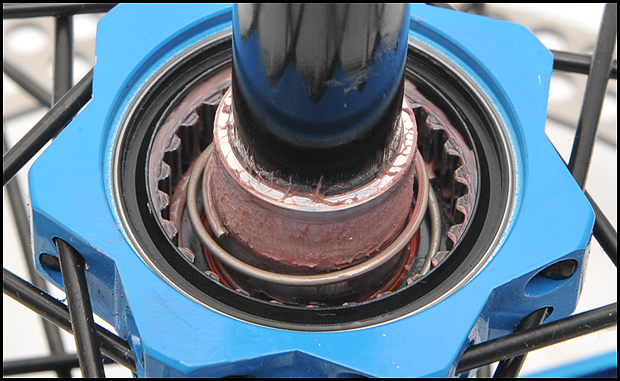

This Halo Supadrive design (which is also used by other companies) is pretty clever. If you were to make a conventional ratchet and pawl system with 120 points of engagement then the pawls would be so fine that they would easily slip or snap. Using lots of of teeth on each pawl though means that the load is spread out over a larger surface, and these pawls slide up a little ramp and wedge securely under load. A simple rubber o-ring stops the pawls from going everywhere when you take it all apart.

As you can see the Supadrive ratchet is very fine indeed, but that’s what gives you the almost instant engagement.

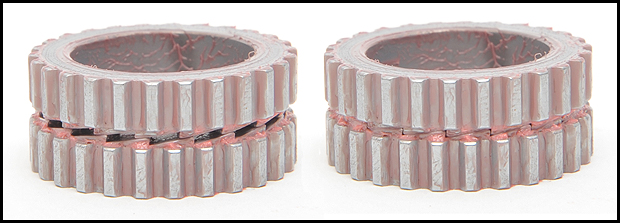

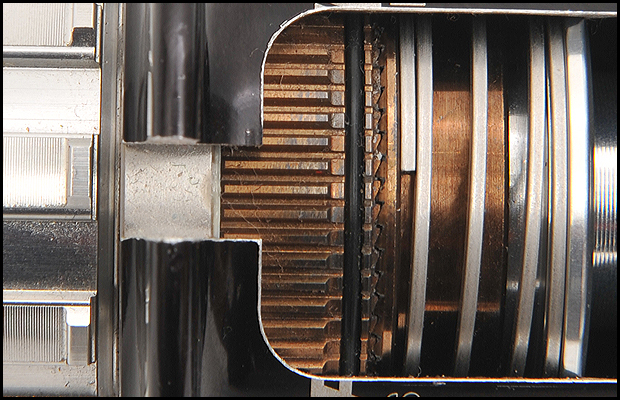

DT Swiss have been using their patented Star Ratchet system for years and although it doesn’t offer the fastest engagement it’s a very reliable system which is also incredibly easy to maintain. The design’s greatest strength is its ability to cope with very high load. The reason for this is that you always have 18 points of engagement, that’s like having 18 pawls!

One of the ratchet plates sits in the splines in the freehub body and is pushed towards the other plate by the spring that you can see.

Just like this.

And then the other plate sits in splines in the main hub body and is again pushed towards its counterpart by a spring.

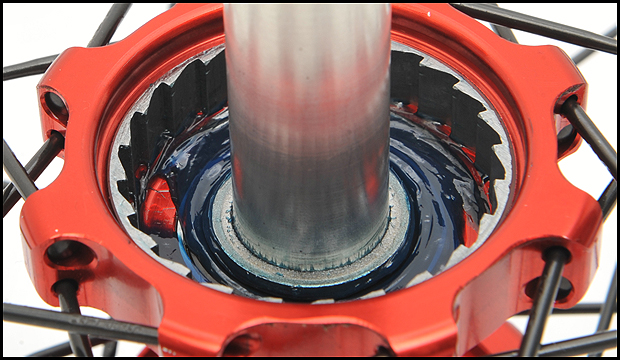

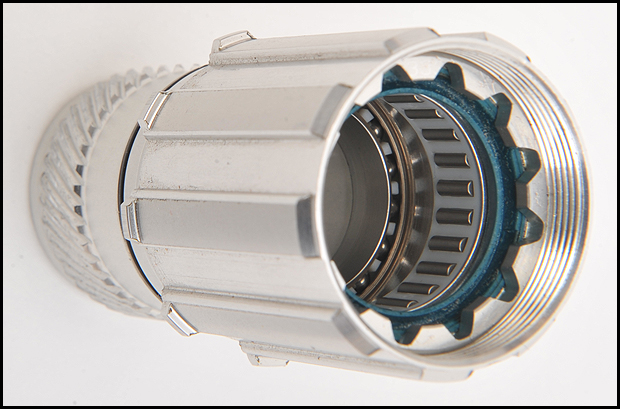

Thanks to this cutaway hub we can see the rarely seen inner workings of a Chris King hub. As you can see the ratchet plates are very fine compared to the DT system, and that’s what gives these hubs their ultra fast engagement. There are 72 positions rather than 18. You might think that would mean that it is more likely to slip under load, but because of the exclusive ‘RingDrive’ design the sprung ratchet plate is forced into the fixed one via an angled spline when you apply toque to the system. The harder you pedal the harder it bites. Also, because Chris King have located this system in the main hub body they’ve been able to make it a larger diameter than the DT system, which means all those teeth can be spread further apart. This system really is something special.

Here you can see the angled splines which help force the ratchet plates together under load. It’s actually very simple, but at the same time it’s highly effective and lets Chris King use a finer system than would otherwise be possible.

And finally just a little look at the other part of what makes Chris King hubs so special (and expensive). You’ll struggle to find better quality bearings anywhere, and just like the rest of their hubs these are all made in-house so you won’t find them anywhere else.

DIRT MOUNTAIN BIKE | NEWS

So, hopefully now you’re a little bit wiser about freehub bodies, but if you’ve got any questions then fire away and I’ll try and answer them. Oh, and if there’s anything else that you’d like to know about/want explained then let us know and we’ll try and sort it out…

see also

The 10 Best Mountain Bike Carbon Bars

MTB GRIPS REVIEWED | HOLD TIGHT!

Six of the Best Mudguards for Winter Mountain Biking

TESTED | DMR VAULT PEDALS REVIEW

RIDER-BRED PROTECTION FROM INVISIFRAME