How do you decide the density of the sole?

We did this through multi-phase, extensive wear-testing, along with pressure data capture and analysis of flat-pedal riding.

We started this entire process by consulting with our tire team, footwear engineers, and rubber chemists to tune our SlipNot compound. We reviewed and set objectives for the rubber (What does the rubber need to do? What is the purpose of the rubber?) and from there developed 8 different rubber compounds to take into testing, each with specific durometers, tensile strengths, tear elongation percentages, tackiness, and abrasion resistance properties.

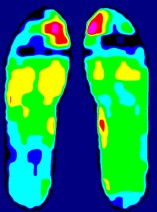

From there, we also knew we needed to tune the material that supports the rubber – the EVA. Soft rubber doesn’t guarantee great ride quality if it’s support structure is too firm. The rubber needs to be soft for pin penetration, and the EVA behind it needs to be soft to subsequently accept the rubber deformation due to the pins. It’s important that these two materials work together for the best pedal connection. This was tuned by first, analysing rider pressure data to see what types of forces to expect, rate of force increase, rate of force decrease, and impact frequency (think of this like your suspension, EVA durometer is like setting the amount of pressure in the air chamber, rate of return and frequency is like your rebound control). From this analysis, we developed 3 EVA compounds to take into testing.

Once we felt comfortable with these variables, we started with a qualitative test with a few of our most sensitive riders (notably Dylan Dunkerton and Curtis Robinson of the Coastal Crew). We spent a few days doing the same run over and over, swapping out shoes for different constructions on each lap, and gathering feedback for how each rode. The shoes were scored against rubber hardness, pedal feel, pedalling stiffness, pin engagement, and pedal connection over varying terrain (big jumps, small jump, brake bumps, rock garden/root section).

From the qualitative testing, we found there were 3 clear front runners that were very close in performance. These are what we took into quantitative testing and had around 20 different riders start logging hours on the shoes. From this testing, we got to our 1 best construction.

What impact does this have on ride quality and damping?

It has a major impact! Our testing (both through data collection and by gathering rider feedback) showed to us that the properties of the EVA (density, thickness, rebound) is the single most-important component to good flat-pedal ride quality. This totally debunks the industry myth that it is all about the rubber.