MADE IN… WORTHING: BTR

In our third instalment of ‘Made in…’ where we look at the resurgence in the ‘hand built’, we visit BTR Fabrications. Burf and Tam Racing (BTR) are just two uni friends with a mutual love of making things, bikes and being creative is a very dangerous concoction for your bank balance. We headed down to Worthing, to have a chat to the men behind BTR. You can check out the feature in the latest issue, #138.

Interview:

So for the benefit of those who haven’t caught up with the web stuff, how did you guys start building bikes?

Ermmm… It was just something I wanted to do since I was a little kid, looking at my parents’ bikes and stuff. I met Tam at uni, and I was like: I want to make frames, and he was like: yeah, so do I. And then I finished uni, got a job as a welder, and then a couple of months later Tam was like: let’s make bike frames then! And we did. We bought a welder, and got some tubes in from Holland and stuff, started making the jig and the tube-notcher. Made a Belter. It worked. So we were like: sweet! Let’s make more!

So how long have you been doing this for?

18 months, or something like that? That’s pretty much it, since we made our first frame…

How did you decide you wanted to make a proper hard-core hardtail first then?

Burf: It was…I used to race downhill for muddy fox and all that kind of stuff and I used to come home here, and after riding all the tracks down south, and then all the local tracks here and stuff, and it just sucked – having a massive downhill bike, and I was like: I need to get a hardtail to have some fun riding my bike when I’m not racing. And then when we went to uni, I said to

Tam: I want a downhill hardtail – a hardtail designed specifically for racing downhill on, and he said yeah, cool, sounds like a good idea. And he started designing it, yeah, he had the design waiting for quite a while, made a fair few modifications to it and stuff…

To be fair, the geometry changed a fair amount… It was meant to have a 63 degree head angle initially, but we realised when we were halfway through building it that it didn’t have a 63 degree head angle! It was like: hmmm…oh dear! But it was just a load of faff, finding where to get all the tubes, and which tubes to use and like that, so the design changed loads just once we’d figured out which tubes we could get, and which bits we wanted and stuff.

So are hardtails more fun?

Are hardtails more fun? Horses for courses, but…

You’re meant to say of course they are!

Yeah… If you just want to go and do big hucks, then you’ll probably survive a bit easier on a full sus bike, but it’s just much more rewarding on a hardtail I guess, so…

Do you reckon hardtails are the way to learn?

Of course they do, yes. Absolutely, you’ve got to think about your lines, missing big bumps and all that kind of stuff. You’ve definitely got to be a lot smoother and all that kind of stuff. A big bike will help you build up confidence quickly though, which is the flip side of it. They will also let you get away with bad habits – not having your heels low, and stuff like that.

So do you reckon the market for hard-core hardtails is getting bigger?

No. It’s getting smaller and smaller as nice suspension works get cheaper.

Do you reckon there is a formula for ‘THE’ bike for a certain type of riding then?

It’s really hard to say in mountain biking because the terrain varies so much, even if you’re on the same track from run to run, same downhill track – if it gets cut up, or it rains, everything is so different.

Haven’t heard that one before…. Makes more sense though!

It’s just so variable; the bike is quite a small percentage of what makes a rider fast, hence why you see people on V10s winning world cups, and all these different bikes, they’re all in the mix, kind of thing – it’s just more the rider than it is the bike. So obviously there is a perfect bike for everything, but if you go on another run, it won’t be the perfect bike anymore, so it’s really hard to say.

So do you just have to experiment a lot with a bike to work out what makes it really good? Or can you work it out on paper?

You can work out quite a lot of it on paper; we haven’t done many significant changes from our first prototype to what we’re happy with, basically our production models, but you can get so much of your testing done just by looking at other bikes, because there are so many bikes available you can say let’s have a ride on this one – what did I like, what didn’t I like, so you can actually figure out a lot of it from other people’s stuff as well as saying I know this head angle works because of the trail it gives.

So there are two big fashion trends at the moment – slack head angles for everything, and bigger wheel sizes for everything. What do you reckon of those?

Well I’d be pretty hard proofed to say we don’t support the first one, because our bikes are ridiculously slack compared with everyone else’s, but there’s only so far you can go on the head angle side, the Belter knocking on the limit because the steering’s all funky when you’re just pootling around on the flat, it doesn’t really work.

Because it’s 61 at static, it gets steeper as you go through the travel so at sag it’s about 63, when it’s bottomed out about 68. But with it being so slack, especially when you’re not far through the travel, if it’s on the flat your weight is transferred a little bit further back and stuff so at your sagged angle the steering becomes a little bit less stable – it tends to pull to one side, and then pull to the other just because of the head angle, so 61, as far as I’m concerned, is the limit to how far we can go with that on the 26” wheel.

And bigger wheels?

Bigger wheels? Well there’s got to be a limit there as well, just for packaging reasons really, bigger wheels is a horses for courses thing – saying that 27.5 wheels are better for everything just can’t be true because there are so many other factors at work – the weight of the tyre, the weight of the rim, weight of the spokes, the stiffness of the spokes, the stiffness of the rim, etcetera.

So there’d be an ideal wheel maybe not for each discipline, but for each track, maybe. And yeah, bigger wheels will roll over stuff better, that’s just easy to see with a 29” wheel on a downhill bike, you have to consider that you’d have a much bigger dual ply tyre adding a ton of weight. Isn’t that going to slow you down when every time you hit a bump you’ll have to move this big tyre and big wheel up and down etcetera, so there’s just a lot more at play rather than just saying 29er’s better, or 650’s better.

The smoothness has got to be a benefit on a hardtail?

Definitely, yeah. Definitely, but you’ve also got a weaker wheel when that wheel’s getting punished a bit more from being on a hardtail, so…

What’s your idea of the ultimate bike? Is there an ultimate bike?

These new enduro bikes are getting closer to the ideal thing – you can ride a hell of a lot more stuff on an enduro bike than you can on say a downhill bike or cross country bike. On a downhill bike you’re pretty much limited to riding downhill, and on a cross country bike you’re pretty much limited to riding cross country so these enduro bikes are allowing you to expand your limits a bit more.

In terms of versatility, they definitely win, I think that’s a pretty good thing really for the average consumer that can’t have 7 different bikes and only have 1. I would definitely be pushing towards that side of things, as well for my ultimate bike.

Just something you can do everything on, really, bit of jumping, bit of downhilling, bit of up hilling… Jack-of-all-trades, master of none.

Do you reckon you can be jack of all trades, and master of most? Better suspension…?

You can obviously make better bikes; the only way is forwards, but…

If you’ve got a bike that can go uphill as well as downhill, it’s not going to be as good as it can be going downhill, or as good as it can be going uphill. It pretty much by definition can’t be done.

It’s a nice question, a lot of people don’t think about it. Apart from the badge, what’s the difference between a hand built and a factory built frame?

The time spent on each different part of the frame and the detailing that goes into it.

It’s definitely time, you could take that, and if we made one – a standard bike, the same shape and everything compared to a factory built standard, we could make them pretty much exactly the same – there’d be no perceivable difference.

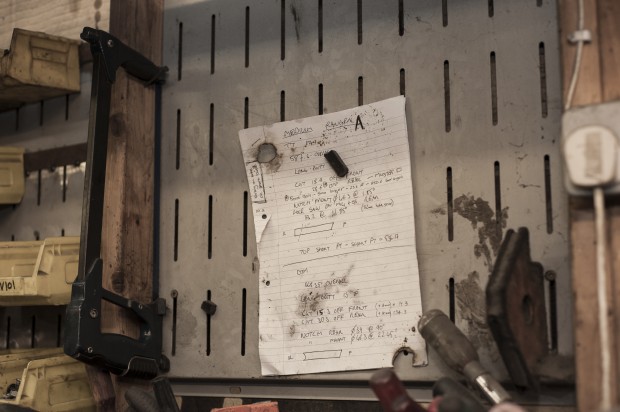

But the difference is how much time we’ve had to put into everything because if someone says they want a bike, you get on the phone to Reynolds and say we want these tubes please and they send them down, and then they say alright, a medium ranger, so we cut this at that angle, and there’s just so much…

Everything still gets done in the factory, in a similar way – the processes are all pretty similar, well they’ll me more automated in the factory but because we have to do everything one at a time, by ourselves we have to put a lot more time into it.

People working in out in Taiwan and stuff they’re just there, well I don’t know – I’ve never met any of these people, they’re just turning up to work. From what I’m like in my day job, I’m just there to get stuff done and go home, whereas when I’m making these frames it’s like a passion – every tube has got to have the burr taken off it. I mean, it makes absolutely no difference to the end result of the frame – once the powder coat is on it you can’t tell whether the edges have been filed or not, but to me it makes a difference, because when I’m working with it I can feel that it’s got a nasty sharp edge on it or something like that.

It’s the hidden things?

Yeah, our frames are made by two guys who love riding and making frames, whereas your mass produced frame out in Taiwan is made by someone who is working for a day job.

But yeah, I was thinking about customisable – if someone phones up and asks can you change this…

Yeah, theirs has got cable guides for front mech, and a dropper post as well as the normal brake cable guides.

Which is not something that we do normally, we wouldn’t normally put a front mech guide on. We can do geometry tweaks and stuff as well – cool custom stuff.

The factories in Taiwan just cannot do that – they can’t just say right, we need to make one of these. They’d have to reset the machines, re-code their CNC machines. They just couldn’t do it, whereas we’re a lot more flexible because we produce on a smaller scale. That’s the major advantage of small-scale frame builders. And if we spot something that we don’t like, we can change it for the next one.

Which has potential, I think, to leave some people quite annoyed, but it’s much better to change things as we know about them rather than wait until 2014, or whatever and then saying: all those frames that we sold you last year, we knew they were a bit dodgy, but… We did one recently, we did a Ranger with a front mech thing – we just put a normal cable stop in the seat tube and as soon as we welded it on I realised that if we’d just extended the top tube a little bit further back we’d have this cable stop built into the back bit there. It was like Doh! So we’ve changed that for these ones, hopefully we can progress faster because of it.

Cheers guys, happy building!