Adrian out testing the new Curve.

Adrian out testing the new Curve.

Building things, anything really, is a big part of riding bikes. From trail building to bolting together a box of bits onto your dream frame, biking is about building in many ways. Even if you are not a mechanically minded bodger or dirt jumper with a degree in sculpture then you will at some point have had to fix something to your bike or stick a shovel in the ground to build something to send your steed down. With time, experience and a background as an engineer Adrian Bedford has taken this ethos of our sport one step further.

You may recall his first bike, the Bedfo’s Super Bike we featured back in 2011. since then Adrian has been busy refining his bikes and has now come up with a second iteration of his full suspension bike which he has sent some details of and a great looking 650b hardtail he has been working on too. It’s bloody great to see people doing this kind of thing and we’ll keep you updated with any more as they come in. Adrian has sent us over some details of how the new Curve has been developed from the previous version and here’s what Adrian has to say.

Old and new, the first bike on the right and new Curve on the left.

I’m calling it the ‘Curve’ and this new frame is a development of the original bike. I have stuck with the high pivot and idler arrangement, I think it offers real performance benefits if you are willing to dump the granny ring and front mech.

Idler pulley setup on the Curve.

There were some areas of the original bike I wasn’t happy with, this new frame addresses these niggles. Firstly I wanted to lower the leverage rate and reduce travel. To do this I have had to totally rethink how the shock is driven. Secondly the geometry is longer at the front, shorter rear and I’ve gone even lower with the BB.

Linkage driven shock rather than the direct swingarm mount on the previous bike.

I’ve also added an adjustment option with a flip chip. (0.5″ higher BB and 1 degree steeper head angle) On top of that there are now two travel options depending on shock, 130mm or 150mm. It takes 26″ or 650b wheels too and rides great with either.

Steel front end, jigged and ready to braze.

As per the original frame I have stuck with a fillet brazed steel front end and carbon swingarm. The front end is a mixture of T45 and Reynolds 853. I went for 853 dzb top and down tubes as they are double butted at the head tube which does away with the need to add a gusset. The seat tube is a plain gauge t45 tube, it takes high loads from the linkage and a butted tube is not strong enough, I’m also now using 44mm headtubes for compatibility with all forks.

Pretty damn neat filleting there form Adrian, a Bicycle Academy day clearly paid off.

Since I built the original frame I have made myself a jig and learnt to braze. I have to mention the Bicycle Academy as I went on their fillet brazing masterclass day which really gave me a big leap forward with my fillets. Before I was able to make strong joints, but hadn’t perfected getting them anywhere near neat and I was spending a lot of time cleaning joints up. Now I’m spending much less time on clean up and don’t find brazing stressful any more! Anyone wanting to learn bike building skills, give them a call, they’ll get you going in the right way. I braze using oxygen and propane to keep things simple.

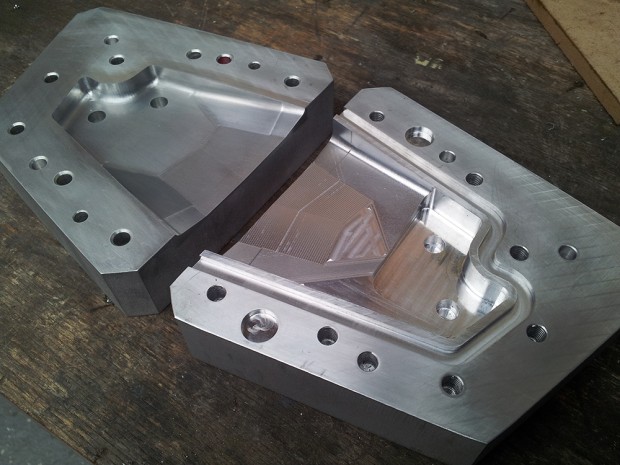

Two part female mould for the dropouts.

The swingarm is now completely moulded in female moulds and consolidated with inflation bladders. I machined some of the tooling from aluminium and the rest was quickly cobbled together in glass fibre to get some prototype parts made. The new swingarm is a full pound lighter than the original and it’s still way overbuilt. The linkage runs on polymer bushes (similar to shock bushes) and all the hardware is stainless.

Vital Statistics:

(15.5″ small frame with 140mm Rockshox Revs and 26″ wheels, 650b adds 0.5″ to bb height)

Top tube length 22.8″

BB Height 12.5 (low setting) 13″ (High setting)

Head angle 65.5 (low) 66.5 (High)

Seat tube angle 74 (low) 75 (high)

Chainstay 16.9″

Wheel base 44.9″

130mm travel (200 x 50 Shock)

150mm travel (200 x 57 Shock)

68mm bb shell

31.6 seat tube

44mm head tube

135 qr, 135 x 12 bolt through or 142 bolt through compatible with replaceable dropouts

26 or 650b wheels (yes they are compatible in 150mm mode too!)

The finished frame and swingarm.

So far I have made a single prototype frame that has been taking a battering for the last few months, it rides really nicely. I have had a few issues with finding a nice shock tune but in general the frame rides really well. I’ve used it with various different forks and swapped between 26″ and 650b wheels. It’s a really versatile bike and a load of fun! I’ve only run it in the 130mm configuration so far and its coped fine with everything including a week in the alps. The high pivot comes alive when it gets rough!

I have just finished off a load of minor design improvements to give better mud clearance and make things easier to manufacture. I’ve also been working closely with the guys over at Cane Creek to slightly improve the shock curve for both travel configurations. Those guys need a shout out, true professionals and more than happy to help out one guy in a shed!! I’ve got a few DBair CS shocks on the way for the demo frames which is really exciting.

I’m now working hard on machining the rest of the swingarm tooling in aluminium. Once this is done the next step for me is to build 4 more frames (one in each size) as test/demo frames. If these work out well I will start to think about producing the Curve frame in small numbers to sell, thats my long term goal.

I think that covers pretty much everything, as with all one off or first goes, this frame has been a huge effort to make, I’ve done every single thing myself in my little workshop in my back garden. Its been a great learning process, the next ones will be quicker and better for sure!

Check out my Facebook page to see how things progress.

Cheers,

Adrian

So there you have it, the story of what can be done with some dedication, we might not all be aspiring frame builders but Adrian’s story may well inspire you to get that old hardtail up and running or even put pencil to paper and design something you have always wanted. Check out the gallery below for all the photos plus some shots of his 650b hardtail.