Findham Strain tells us about his homemade carbon hardtail, the Comeragh N56, that he made in his front room!

This is my Comeragh N56 carbon hardtail. I was out of work for 3 months during early 2010 and thought I would give the homemade bike a go. The reason behind making a hardtail was to gain experience in making a downhill bike. The design spec was to make sure that it could be a hardcore hardtail. So this meant, in my opinion, short stays and generally a short frame that would be capable of taking untold amounts of abuse.

The desk above was my workstation. What you may not realise from this photo is that, that’s the living room of the house I was renting and the overall room was maybe only 3 times the size of the area that you could see in that photo. Plus, I was living with two of my friends, whom I have lots of respect for, for putting up with all that crap.

The first competitive outing was at the Epic Blast in September 2010, a couple of months after the first ride, where it got tested to its limits; lots of hard square edged bumps, flat jump landings and the most abrasive muck you could ever imagine! Having raced there, I had a good confidence that the bike could take a bit of abuse!

Bit of background:

I’ve a degree in engineering, a love of bikes and am a professional hash – I’m proof that you need only minimal talent and plenty of commitment to do something you want to do! I have had experience in working with carbon before but with higher end materials. It was actually tricky to take a step back and focus on some simple aspects that are often overlooked as an engineer!

Design Spec:

The purpose of this bike was to gain experience at manufacturing. Time and time again, you see people design the most elegant products, be it bikes, cars, whatever, but being able to manufacture it is generally a stumbling block.

My dream is to build a carbon downhill bike, so I wanted to gain experience by making a simpler product first, ie a hardtail. Being someone who is generally used to office chairs, I wouldn’t be overly great with my hands, so I really needed to get manufacturing experience, so I spent very little time on the design. I wanted a really hardcore hardtail that could take a thumping but was good at pedalling too, as up until that point I had ridden nothing but downhill. Hell, I barely knew the proper design features of an XC bike. Anyway, all the geometry was made up by myself, with short stays, short frame and a 67.5 degree head angle or so being the order of the day.

So, simplicity and keeping cost to a minimum were key factors in the project throughout. I also wanted to make sure I finished the project and not stop half way through.

General Manufacturing:

I got the carbon through a company called Carbonology in England as I had been in touch with the owner previously. They, along with other companies such as Easy Composites can supply this material. Even in the last year, there are a good number more suppliers of the material in Ireland and the UK. The grade of carbon isn’t overly expensive, the resin I used was a West Systems Pro-Set 125 resin which is slightly better than standard West systems epoxy.

The carbon is approx £30 per square metre, cant remember how much the resin was but I think it was over £200. Then, also prob spent about £200 on adhesives for loaded structures (e.g. dropouts), applicators and all that carry on. And of course postage for some stuff is a nightmare and over the whole project prob cost a lot!

Whole thing cost just under 2k with tools and all included I reckon. So….yeah, no new car for me!

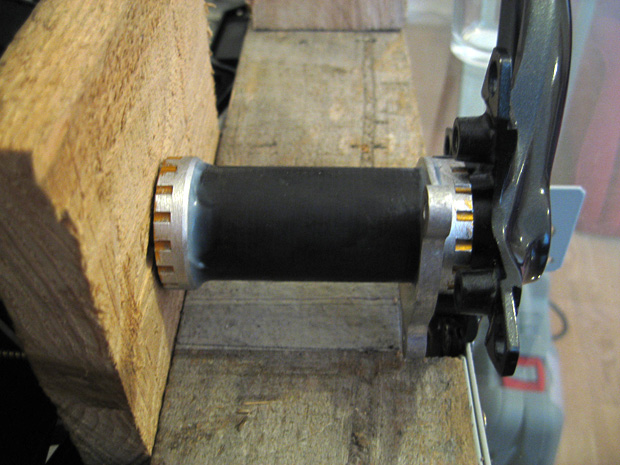

I started manufacturing the headtube and bottom bracket first. I made these myself using uni-directional carbon and a 2×2 twill weave carbon taken off aluminium moulds that I turned on a lathe.

What made life a lot easier was that I bonded in bearings at the headset and bottom bracket. Again, remember my objectives – simplicity and just making the damn thing! More to the point, I didn’t expect to ride this bike too much and thought that bearing life wouldn’t be an issue.

I then used carbon tubing covered in a polyurethane foam to form the shape of the actual frame. This was all shaped by hand and essentially constituted a male mould: Female moulding for one off frames is just entirely impractical on my budget!

You can also see my wonderfully elegant jig that I made out of nicely warped timber. It just shows you that you can make good things with crap stuff if you take your time (or are talented which I certainly am not-takes me 20 times longer to do something that normal people do easily) I could have bought plenty of good materials for a jig, but had to keep reminding myself of my design spec-cheep and simple.

For the frame, once again, I used UD carbon and 2×2 twill aligned at certain angles and varying thicknesses depending on the location. I used a good room temperature curing epoxy resin that was eventually post-cured at 50c in a homemade oven made from timber, kingspan, standard heaters and two thermometers just to keep it reasonably consistent.

The resin and carbon were slightly higher grade than commercially available materials, as I wanted to try to ensure it wouldn’t break on the first ride!

Other Components

I got the dropouts from a Kona Stab of mine that was due some new dropouts anyway! They were slightly modified and bonded into form a super strong back end.

The brake mount inserts, again, were butchered from an old frame I had and bonded into the surrounding structure.

Finished Bike

Having laminated all the layers and sanding like a mad man for ages, the bike was finally ready to be lacquered. I got a local paint shop to lacquer it for me with an automotive lacquer to finish it all off. (The lacquer weighed a ton!)

Finished weight; don’t actually know, Its about the same weight as an aluminium frame, maybe a little lighter, as I over-engineered it, but wasn’t going to do anything else on a first attempt! I finished the bike off with some crappy components then again as I wasn’t expecting to ride it too much!

In Summary

All in all, it has been a life changer and has openend up a world outside of downhill that I didn’t know existed. The bike has been through everything, downhill races, XC races and all types of free-riding. It has hit rocks, trees, animals, landed gaps, drops, hit some seriously hard flat landings and it is still going strong. Oh….guess what….I had to change the headset and BB bearings about 3 months ago…Result!

After building the bike up with some rubbish components (didn’t expect the frame to last!!) The first outing was in Glenveagh National Park, and took quite a few hard hits, but somehow it survived!

Opening up new worlds.

Having always been too fond of gravity riding and using nothing other than big bouncy bikes, this bike has been a game changer in my life. It has opened up a completely different world that wouldn’t have been possible without it and that is why I have such love for this bike. I am privileged enough to live in one of the most spectacular places in the world; Co. Donegal in Ireland where the scenery and completely untapped hills can provide the most epic rides.

XC Racing

The bike was never designed as an XC racer in any shape or form, but it was a hell of a lot more pedal-friendly than my DH rig! In fact, I probably put up more miles in my first few months on it than I had in my whole life cycling. However, I did have its pedal friendly approach in my mind throughout the design.

The frame is too short for climbing and can result in a slightly sore lower back at times, but, at the same time, I did three or four races on it and I could never have imagined racing XC a year earlier.

DH Racing

Growing in confidence in the bike’s big-hit ability, I thought it was time to hit the dh races. Ive been at a few races with the downhill bike in the van and thought, ‘nah’, think I’ll take out the hardtail because it is just so much fun.

So, I’ve now raced it a number of dh races and have subjected the poor wee thing to endless amounts of torture and some nice jumps too! I could recommend that everyone races a dh race on a hardtail at some stage and you’ll really see what racing is all about and thats having a bit of craic. Leave your Troy Lee pyjamas at home, stick on a t-shirt and go beat your bike off some rocks and jumps!

Next Bikes

I’m currently making a downhill bike and have plans for an AM bike; however, my manufacturing methods are now more complex and costly! Sometimes its hard to get the motivation to get up off the couch in the evenings after work and get stuck into some more work, especially as you only have an hour or so before bed-time!

The more complex methods of manufacture have led to the back end of the dh rig being completely scrapped! A lot of money and time goes into a homemade bike, so its really crappy to see £4-500 down the drain and months of work, but if its anything like my hardtail, then it will be worth it!

Findham Strain

Have you built your own frame? If so, get in touch with Billy