And here is the ‘Fact Sheet’:

Robot Bike Co.

ABOUT US

Founded in 2013 by Ben Farmer, Ed Haythornthwaite, Andy Hawkins and Ben Robarts-Arnold, and in close partnership with of one of world’s foremost suspension designers Dave Weagle, Robot Bike Co. is all about creating great mountain bikes, engineered and bespoke.

We design and manufacture lightweight, custom geometry, full suspension frames that are unique to each and every customer.

We use cutting edge manufacturing technologies because we know how and when to best apply them. Our design & engineering is grounded in years of experience in the cutting edge world of aerospace, F1 and automotive, and our DW6 suspension design has been developed and tailored in partnership with Dave Weagle to provide the ultimate suspension.

We’ve developed a unique construction technique which allows a design freedom for each customer to specify the exact bike they want, one that fits just right, and we have worked at the cutting edge of simulation, test and analysis to validate our frame performance.

And we’re doing all this right here in the UK.

THE TEAM

Ben:

Used to be quick. PhD, and Chartered Engineer with a taste for carbon and titanium. Ben has spent years as an aerospace engineer, materials scientist and inventor and is now putting all that to good use engineering our frames.

Dave:

Dedicated to improving leisure through science. A lover of dirt, acceleration, wheels, people, dogs and music.

Robot:

Inspiration for our company name, bike loving mechanical engineer with a sensible chip making sure all the tricky bits and pieces come together as they should.

Andy:

Industrial designer, spent a career in F1 and aerospace developing additive manufacturing technologies. Now its time to apply those skills to something I love.

Ed:

Frame builder, World Cup Downhill mechanic, Technical Editor at Dirt Magazine, Racer…Ed lives and breathes bikes and has done pretty much since the day he was born.

Rob:

Product designer/CAD wizard/bike nut/problem solver, and with an impressive background in the aerospace industry Rob is a more than welcome first addition to the team.

R160

The R160 is Robot Bike Co’s first frame, and whilst it may be our only one at present, this could well be the only bike a customer needs. With aggressive geometry and 160mm of travel the R160 thrives in steep and technical terrain, yet at the same time it is equally at home on climbs and all day epics. The unique DW6 suspension system plays a key part in this versatility. The progressive leverage ratio provides the suppleness you need for grip at the start of the travel, support in the middle, and a bottomless feeling at the end for when you’re really pushing things, perfect no matter what situation you find yourself in. Of course alongside grip and composure you also want a frame that pedals well, and once again the DW6 design won’t leave you wanting, the R160 is as efficient as they come.

We believe that 27.5” wheels are the perfect partner for a bike of this nature as they offer great speed whilst crucially still being able to handle the sort of thrashing that they are likely to encounter on the R160. You’ll also find a 12x142mm rear axle for maximum compatibility purposes, and a proper threaded bottom bracket (no creaking here!). Talking of threads, apart from the bottom bracket ones you won’t find a single thread anywhere else on the titanium parts of the frame. We’ve seen too many frames written off by damaged threads, so all of ours are easily replaceable should that ever be required.

All of the unique engineering that has gone into the R160, and the effort to create it, would be worthless if the frame didn’t fit a customer perfectly, and that’s why we believe a custom fit is so important. Once we have the customers measurements we will provide them with our recommend geometry. That recommendation will be based upon what we believe provides the ultimate blend of speed, fun, stability and agility. If they have different priorities/requirements then for a small extra charge we are more than happy to discuss these with them and work out what is best for them in order to create something truly bespoke, but we believe that the vast majority of riders will love our suggested geometry as much as we do.

TECHNOLOGY

CUSTOM FIT & GEOMETRY*

Due to our unique construction method all our frames are configured to a customers specification. Our baseline frame design has been developed in partnership with the engineering design company HiETA using advanced CAD and simulation tools with a parametric CAD engine which allows us to quickly input the fit and ride requirements and output a design in an automated process.

*Pending patent application number GB 1605178.1

DW 6 SUSPENSION

A new suspension platform designed and developed by Dave Weagle for Robot Bike Co. The design allows for ultimate independent control of the critical aspects of the suspension kinematics. When combined with additive manufacturing this means we are able to produce the best possible suspension characteristics without compromise.

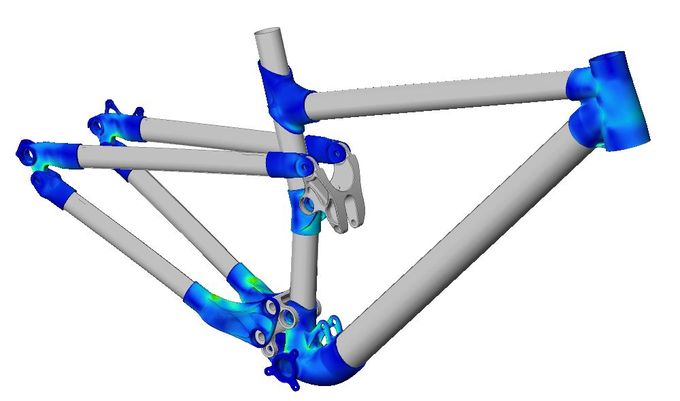

OVERALL FRAME ARCHITECTURE

We take the best characteristics from aerospace titanium and carbon fibre materials to provide you with a strong, resilient and lightweight frame. In short, composites work well when shapes and loads are simple – a wing spar for example. Metals work well in areas of high shape complexity and when loads come from different directions – aircraft landing gear for example. To take advantage of these fundamentals we put high strength to weight ratio titanium in the areas of maximum stress and connect these together with high stiffness to weight ratio carbon composite tubes. Then we move the joint away the area of peak stress and employ a state of the art double lap shear joint design.

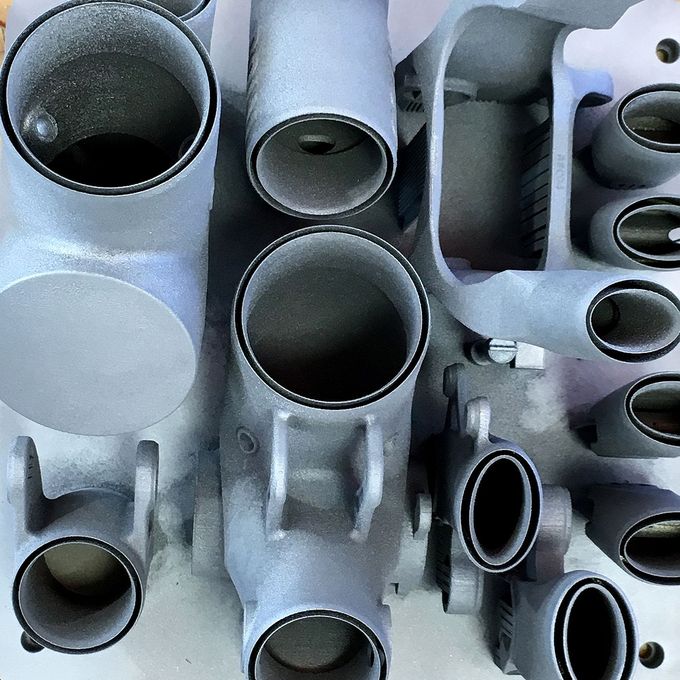

TITANIUM ADDITIVE MANUFACTURED LUGS

By adopting this cutting edge manufacturing technology currently being implemented in the aerospace industry by the likes of Airbus and GE and widely used in Formula 1, we have the design flexibility to create custom geometry frames, and the ability to create novel joint interfaces. Titanium (aerospace grade Ti6Al4V) gives the optimum strength/weight solution for these loaded areas of the frame, and works fantastically well bonded to carbon fibre laminates. In partnership with the engineering company Renishaw, our lugs are batch processed by Selective Laser Melting, with Ti powder particules in the 10-45um range fused together by a high power fibre laser, heat treated for optimal mechanical performance and then CNC machined for bearing, headset and bottom bracket fit. Our ‘double lap pi joint’ design is made possible by this manufacturing process, along with the ability to make every lug set bespoke to order. This manufacturing technologies should not be confused with other technologies commonly referred to as ‘3D-printing’. We are using the same Laser Powder Bed Fusion Additive Manufacturing technologies as described is the draft SAE standard AMS 7003 in development by Airbus, Boeing, GE and Rolls-Royce amongst other to control the manufacture of safety-critical aerospace parts.

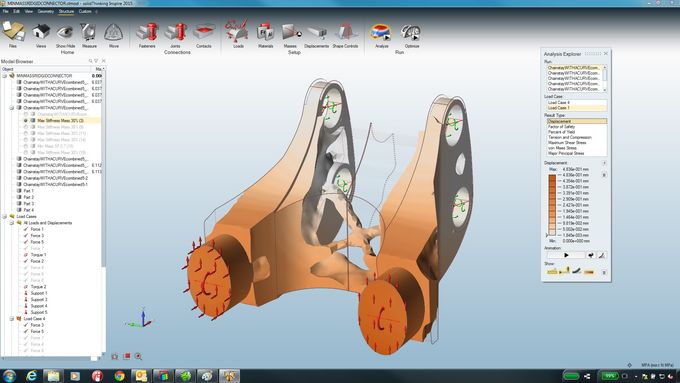

FEA & TOPOLOGY OPTIMISATION

Topology optimisation is a mathematical approach that optimises material layout within a given space, for a given set of loads and boundary conditions, to provide the lightest weight design possible. Topology optimisation is a perfect fit with Additive Manufacturing as for the first time design concepts generated can actually be manufactured. Furthermore the maximum loads in the material can be controlled to avoid stress-raisers and employ a principle called ‘infinite life design’. The results of this are quite subtle in most areas of the frame as the ‘boundary conditions’ are quite high. For example the headtube lug needs to accommodate round carbon tubing , fit a round headset and not fill with mud – what is less apparent is the fine control over the wall thickness to achieve a light weight. The most apparent result of topology optimization is the chain stay yoke where the design is much less constrained. The market leaders in topology optimization software and its use is Altair. This approach, in partnership with Altair, has been used by Robot Bike Company to ensure that our frames are light weight whilst avoiding metal fatigue meaning that we can offer a lifetime warranty to the original owner and you a frame that will be great to ride and enduring.

CARBON FIBRE TUBING

Carbon fibre reinforced polymers work by far and away better when fibres are kept in close alignment to the loading direction. A deviation of just 0.25 degrees (~4 mm in 1m) reduces compression strength by 1/3. We use aerospace-grade Mitsubishi-Rayon TRH50/NB301 and MR60H/NB301 pre-preg materials and uniform shapes to guarantee fibre alignment, both in-plane orientation and out-of-plane wavyness, for maximum strength and stiffness. The lay-up schedule for each tube and fibre is proprietary and specific to each tube to ensure that each tube is optimal. We avoid sharp corners, such as those found in square section tubes, as these lead to “corner unfolding” when the composite is loaded through-the-thickness rather than in the plane of the fibres. Our approach means that we utilise 100% unidirectional fibres and not woven fabrics as we believe that performance is more important than what is perceived to be the ‘carbon look’. The result is our tubes are as strong and as stiff as they can possibly be giving you a lighter more resilient frame.

DOUBLE LAP SHEAR JOINTS*

Double lap shear joints, sometimes called pi-joints due to their similarity in shape with the greek letter π, are used on Robot Bike Company frames. Pioneered for use in aircraft construction by Lockheed Martin, double lap shear joints are the best joints to avoid ‘out-of-plane’ loads and therefore ensure maximum joint reliability. The use of Additive Manufacturing means that higher aspect ratios and thinner walls with much greater control over wall thickness tapering can be achieved than if machined or cast. Pi-joints also allow for the use of the ‘insertion-squeeze-flow’ method of bonding ensure even surface coverage of the aerospace-grade two-part epoxy Henkel adhesive used. Aerospace surface preparation practices combined with our design and Additive Manufacturing process means that Robot Bike Company’s joints are more efficient than any others known to be use in aerospace or Formula 1 applications. For you this means the lightest weight and most reliable frame possible.

*Pending patent application number GB 1605177.3

STRUCTURAL TESTING

Robot Bike Company has employed aerospace ‘test pyramid’ methodologies to the structural validation testing of the frame. Starting at the ‘coupon level’ small test pieces have been testing by aerospace test-house Exova to provide material data to feed into the Altair software. Next at ‘element level’ the double lap shear joints between lugs and tubes has been tested. Then at ‘component assembly level’ the full frame is tested to ensure compliance to relevant standards. Loads described by international standards are, in fact, much kinder than those we design against so finally the frames are built up into bikes are ridden hard by an World-Cup level test rider.

www.robotbike.co

The use of MDM in bicycle manufacture is not necessarily new. Charge Bikes were using it a few years ago on a project making dropouts for one of their hardtail bikes, Empire and their MX6–R, there is also an Australian road company called Bastion (who were at the recent Bespoked bike show in Bristol) that uses very similar ideas with printed parts and carbon tubes, but in full suspension mountainbikng, and on this scale… well, we haven’t really seen it before.

The use of MDM in bicycle manufacture is not necessarily new. Charge Bikes were using it a few years ago on a project making dropouts for one of their hardtail bikes, Empire and their MX6–R, there is also an Australian road company called Bastion (who were at the recent Bespoked bike show in Bristol) that uses very similar ideas with printed parts and carbon tubes, but in full suspension mountainbikng, and on this scale… well, we haven’t really seen it before.